Satsuki Kako Co., Ltd., based in Machida City, Tokyo, specializes in laser marking on a vast array of substrates—from metals to plastics—and is driving both precision and sustainability forward in manufacturing.

Company Background and Founding Vision

Satsuki Kako was launched by CEO Yasunori Kimura after he witnessed growing demand for high‑quality marking solutions while working as a technical specialist at Yokohama Systems, a Kanagawa‑based equipment distributor. Drawing on that experience, he established his own laser‑marking venture to serve manufacturers’ evolving needs.

Versatile Material Capabilities with Advanced Laser Systems

Multiple Laser Modalities for Every Surface

- Fiber lasers, CO₂ lasers, UV lasers, and diode lasers are all deployed to mark stainless steel, aluminum, copper, and other metals.

- The same suite of systems handles ABS, engineering plastics (PBT, PPS), polypropylene (PP), polyethylene (PE), polystyrene (PS), and even wood and ceramics.

3D Scanning Integration for Complex Geometries

- A built‑in 3D scanner maps object contours in real time.

- Marking on flat panels, cylindrical components, and free‑form curves is achieved without loss of precision.

Contributing to Eco‑Friendly, Sustainable Manufacturing

Laser marking at Satsuki Kako is entirely solvent‑free and non‑contact, eliminating the need for inks or etchants. This low‑impact process aligns with SDG principles and reduces waste. For example, at a recent Sagamihara City event, the team laser‑engraved biomass‑derived cork products, showcasing how green substrates and clean processing can combine to deliver sustainable branded goods

Challenges for SMEs in Advancing SDGs

Yasunori Kimura highlights two main hurdles for small and mid‑sized manufacturers:

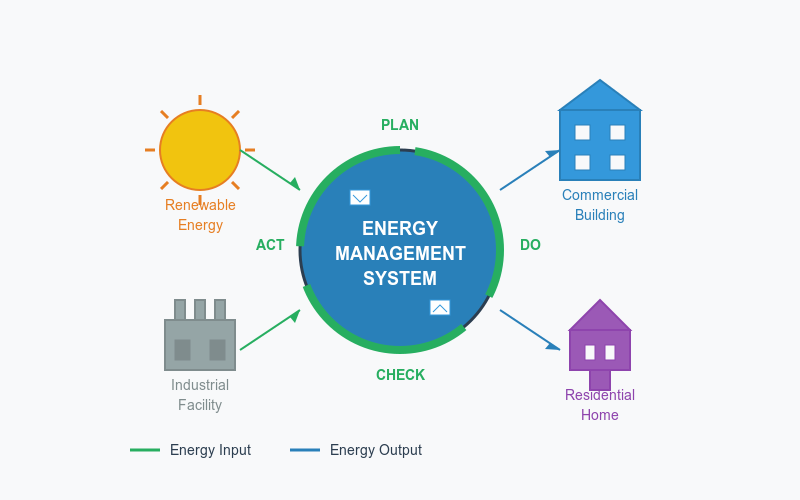

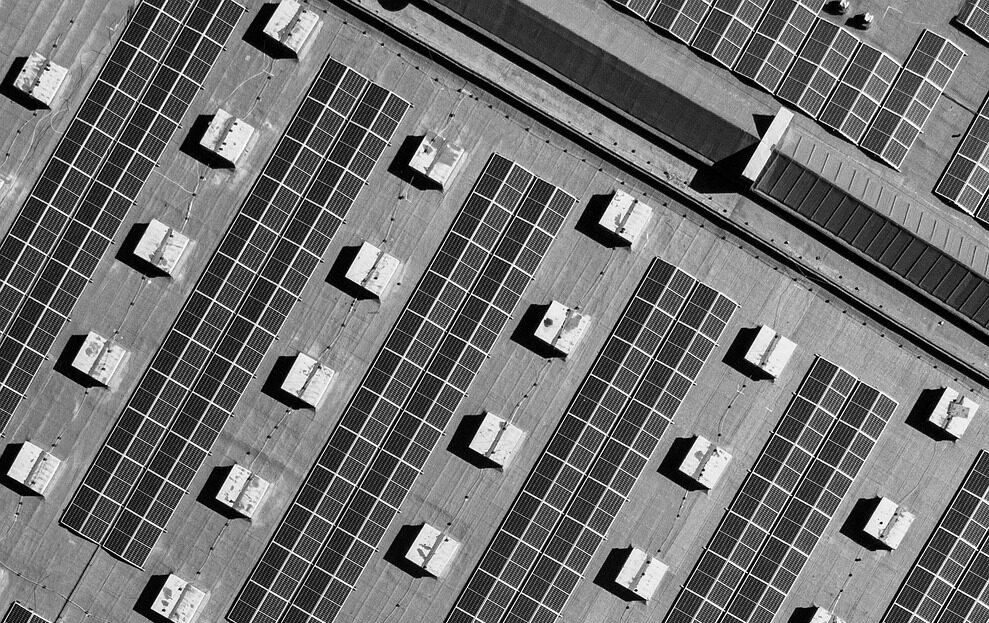

- High capital investment — Advanced equipment such as solar panels or laser rigs demands significant up‑front outlay.

- Technical power requirements — Industrial lasers often need 300 V supplies, whereas typical household outlets deliver only 100 V.

He stresses the need for greater government and industry‑association support to lower these barriers and accelerate greener manufacturing practices.

Regional Collaboration and Strategic Outlook

Satsuki Kako maintains strong ties with local partners and its former employer, Yokohama Systems, to leverage customer referrals and co‑development opportunities. Looking ahead, the company plans to:

- Develop new laser‑marked product lines, such as customized industrial components and consumer‑facing goods.

- Partner with municipalities and trade bodies to host SDG awareness workshops and demonstrations.

- Balance aesthetics and sustainability, pursuing marking techniques that enhance product appeal while minimizing environmental impact.

With “beauty” and “sustainability” at its core, Satsuki Kako aims to remain at the cutting edge of laser marking technology and regional industrial revitalization.

Leave a Reply